+86-19862000127

+86-19862000127

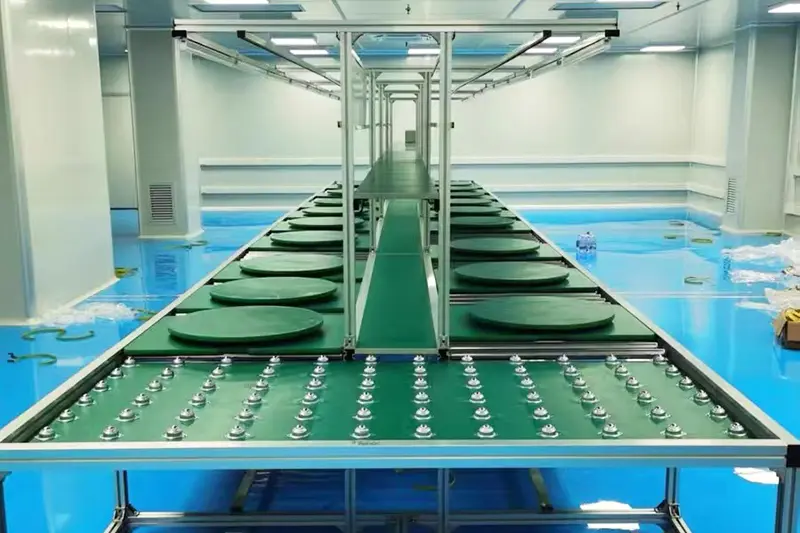

PVC lightweight conveyor belts

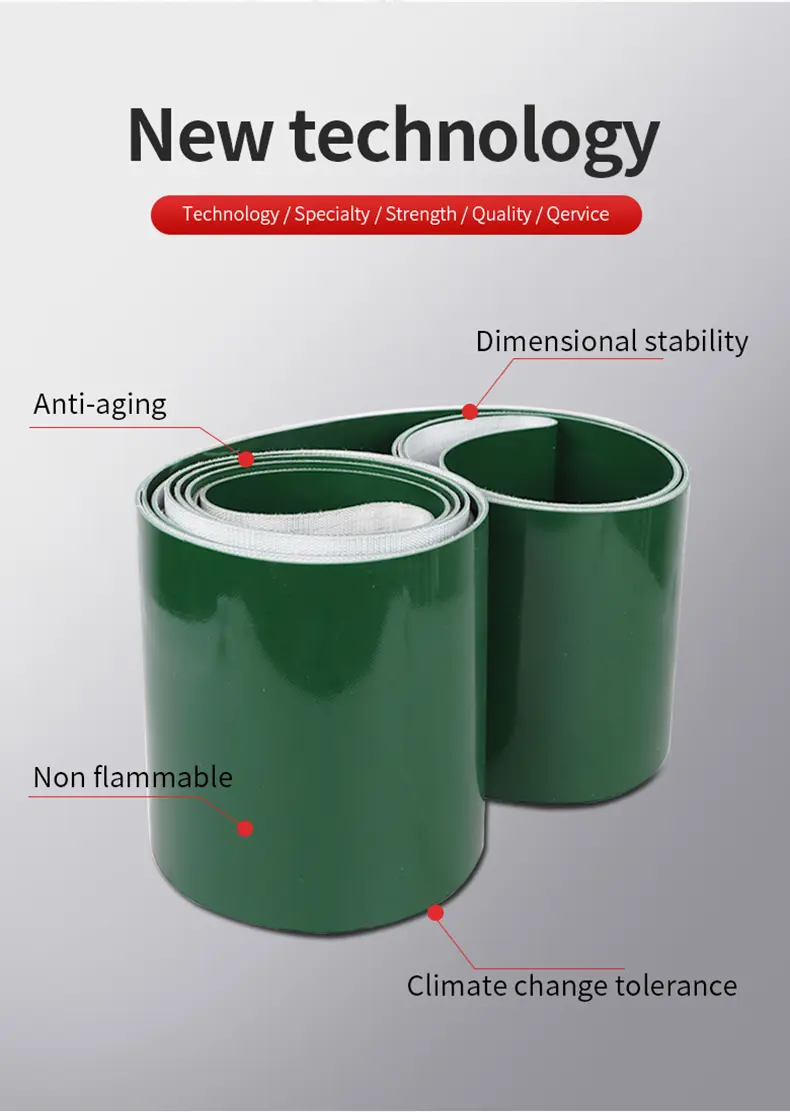

Product advantages

1. Cost advantage: The production cost of PVC material is relatively low, making the price of PVC lightweight conveyor belts more competitive in the market. In addition, PVC conveyor belts have a smooth surface and are not easily adhered to materials, making them easy to clean. They also have good chemical stability and are not easily corroded by general chemicals, thereby reducing maintenance costs

2. Wear resistance and chemical stability: PVC lightweight conveyor belts have excellent wear resistance and can maintain stability during long-term high load operation, reducing wear and damage. At the same time, it has good tolerance to chemicals such as acids, bases, and salts, and can work stably in various chemical environments, extending its service life

3. Processing and application advantages: PVC material is easy to process and shape, and can be manufactured in various ways to produce lightweight conveyor belts with different specifications, patterns, and thicknesses, meeting the personalized needs of different users. It has strong plasticity and can quickly and efficiently complete production, improving production efficiency

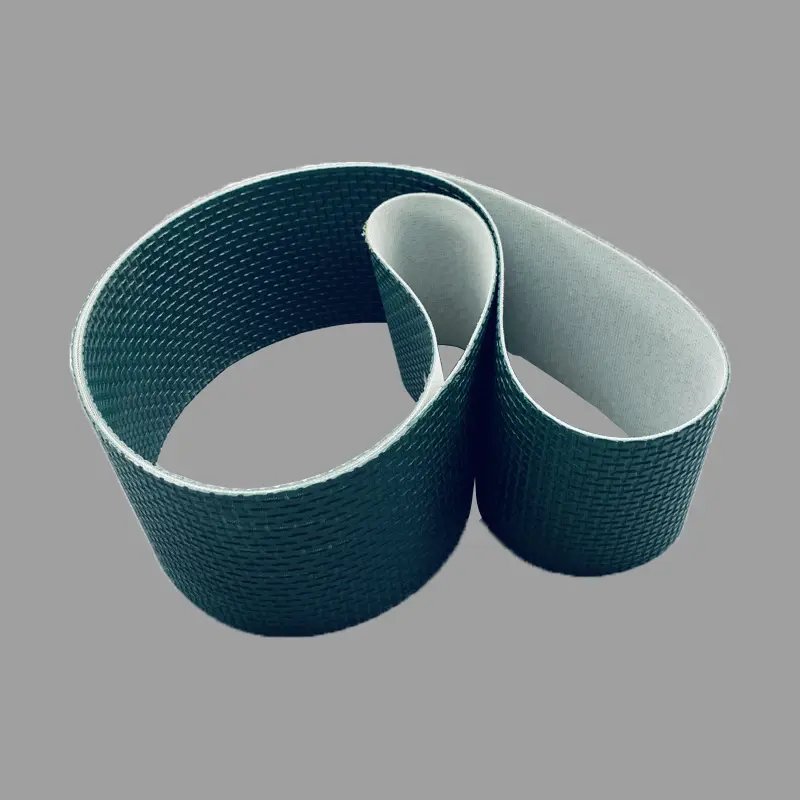

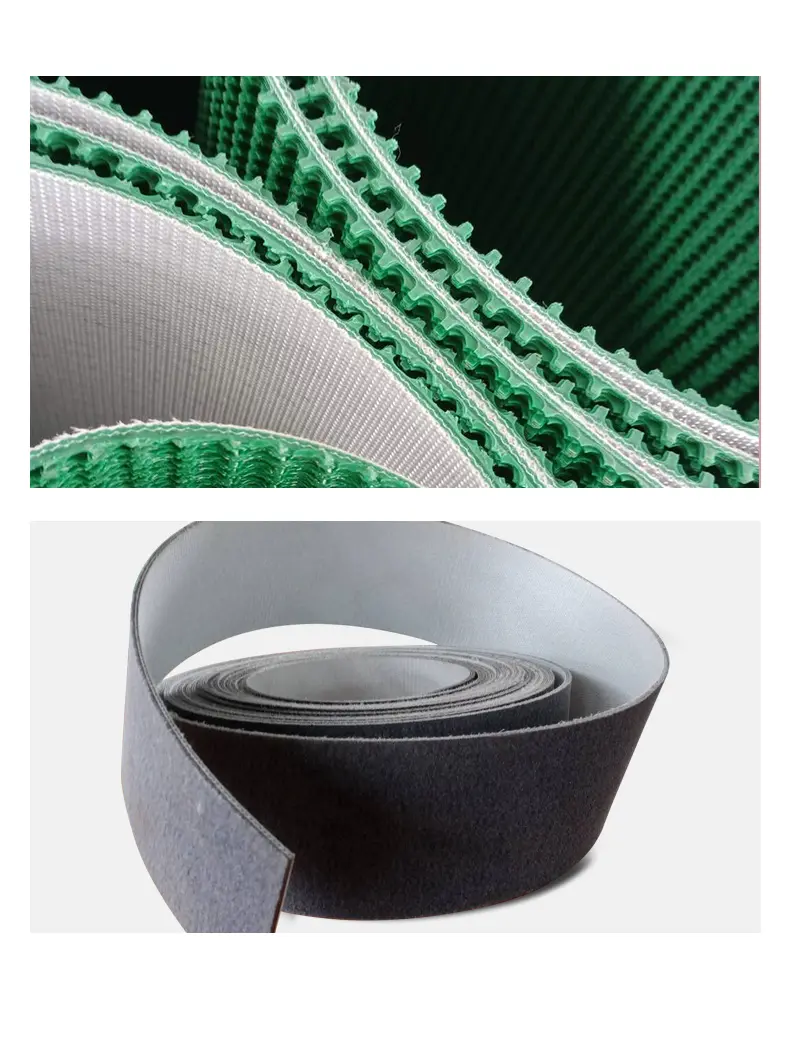

4. Lightweight and flexible: PVC lightweight conveyor belts are lightweight and have good flexibility, which can easily adapt to different conveying paths, especially in environments with limited space, they can still operate effectively. Users can easily adjust the layout and form of the conveyor belt according to the needs of the production line

5. Anti static performance: PVC lightweight conveyor belts can achieve good anti-static performance by adding anti-static agents and other methods, effectively preventing damage to electronic components caused by static electricity. They are suitable for industries that are sensitive to static electricity

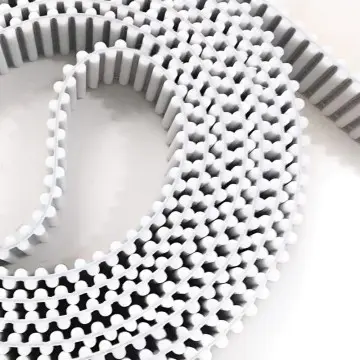

6. Diversified pattern design: PVC lightweight conveyor comes with various pattern types, such as herringbone pattern, strip pattern, grass belt pattern, diamond pattern, diamond pattern, I-shaped pattern, etc., which can effectively prevent material from sliding down during material conveying at different inclinations

7. Hygiene and Maintenance: The formula design of PVC lightweight conveyor belt products is reasonable, meets hygiene indicators, has moderate color, is lightweight and durable, easy to install, and easy to maintain. Especially in the food processing and pharmaceutical industries, its easy to clean characteristics ensure the hygiene and safety of the production environment

Industry applications of conveyor belts

A conveyor belt is a mechanical device that continuously transports materials and achieves automated handling through cyclic motion.

It has the advantages of high efficiency, energy saving, reducing human dependence, and adapting to complex environments such as high temperatures and corrosive environments.

Mainly used in express sorting centers, e-commerce warehouses, port container loading and unloading, food grade materials (such as PU, silicone), easy to clean design, collaborating with robots to complete welding, spraying, assembly, grain drying lines, fruit and vegetable cleaning and sorting, livestock feed delivery and other industries.

Specialized customization can be carried out, combined with 5G and digital twin technology, to promote the development of "unmanned factories".