+86-19862000127

+86-19862000127

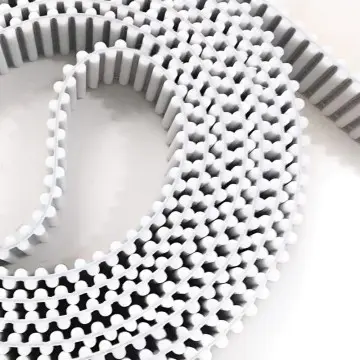

Nylon Timing Pulleys durable and non-conductive

Application

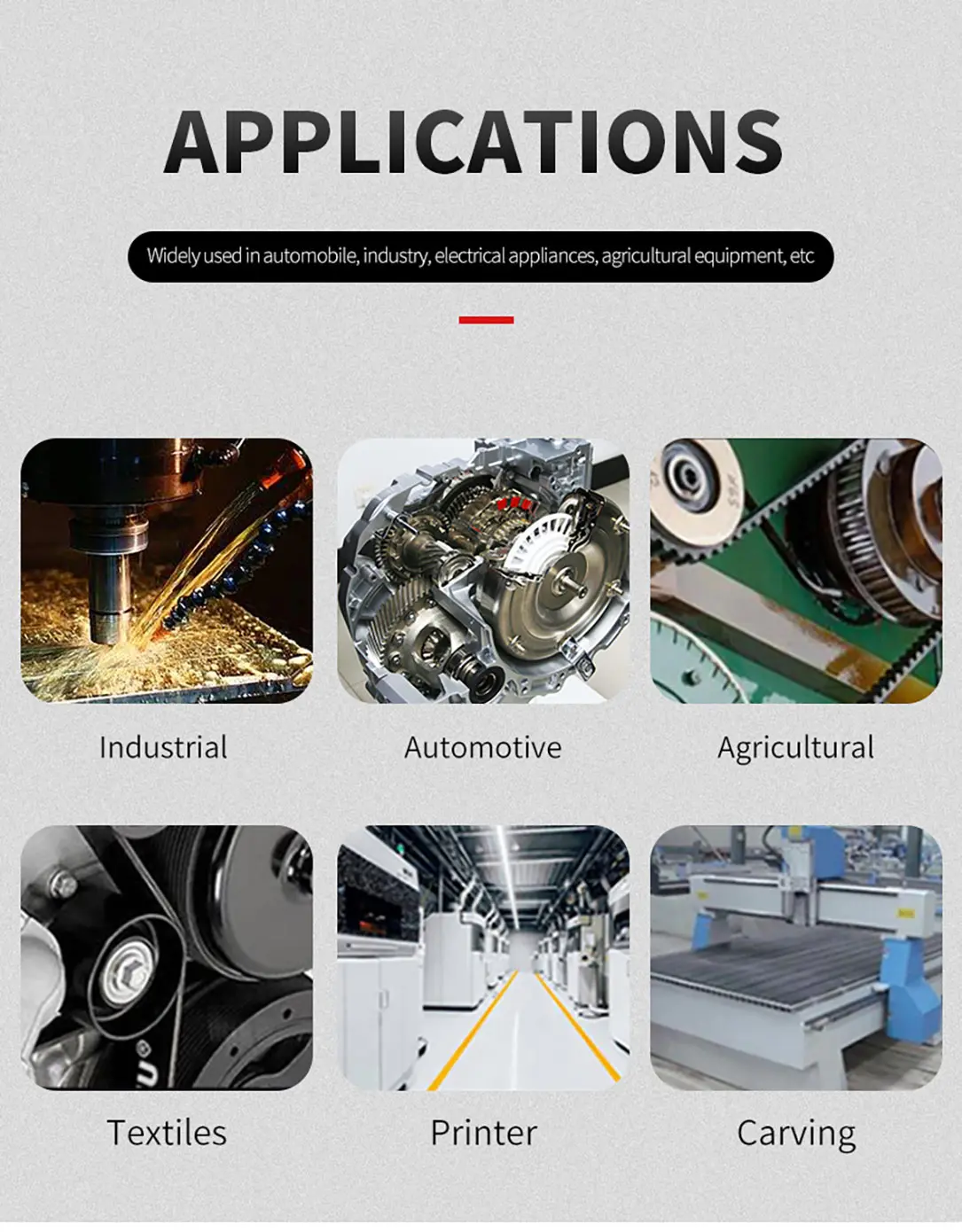

Nylon timing pulleys are versatile components used in numerous industries, including:

- Manufacturing: Integral to conveyor systems, assembly lines, and automated machinery, ensuring smooth and efficient operation.

- Automotive: Commonly used in engine systems and accessory drives, where precise power transmission is crucial for performance.

- Textile Industry: Essential for weaving and knitting machines, where accurate timing and synchronization are necessary for production efficiency.

- Robotics: Employed in robotic systems for precise movement and control, enhancing operational efficiency and accuracy.

- Food Processing: Utilized in food handling and packaging equipment, where lightweight and corrosion-resistant materials are beneficial.

advantage

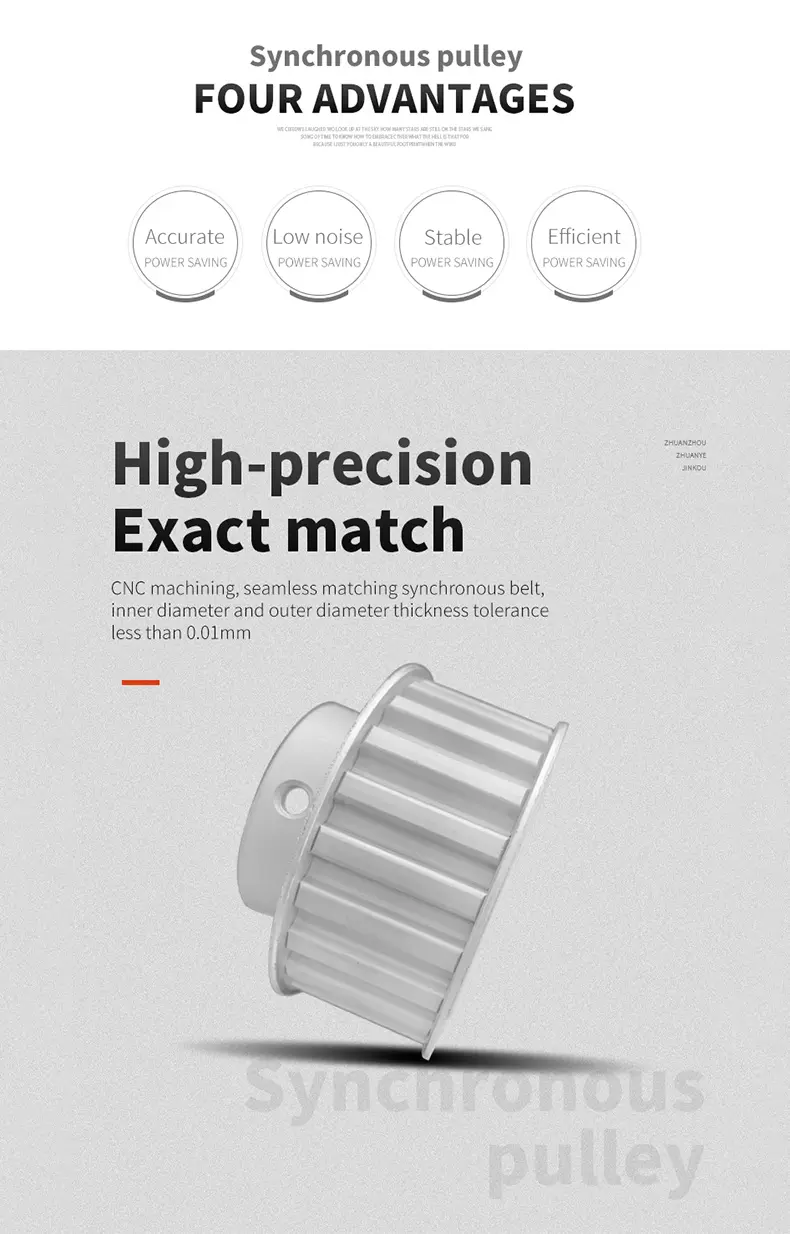

1. Lightweight Design: Our nylon timing pulleys are significantly lighter than metal alternatives, reducing the overall weight of machinery and improving energy efficiency.

2. Corrosion Resistance: Nylon is naturally resistant to moisture and chemicals, ensuring that our pulleys maintain their performance and appearance even in harsh environments.

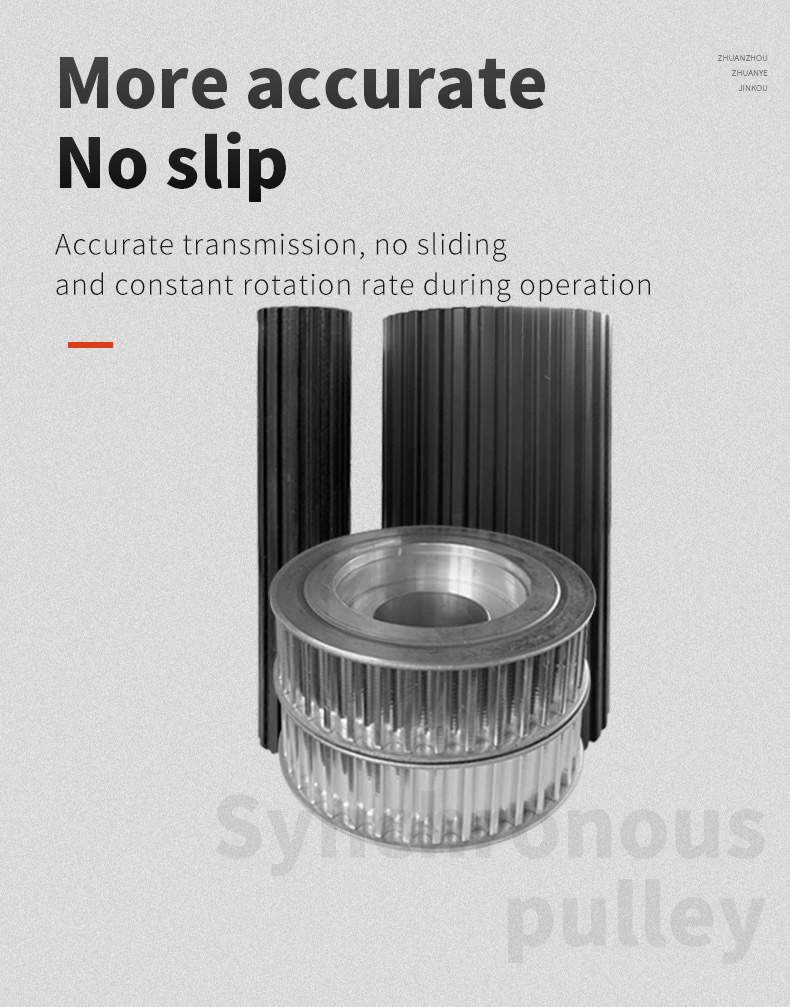

3. High Strength-to-Weight Ratio: Despite their lightweight nature, these pulleys offer excellent strength and durability, making them suitable for demanding applications.

4. Low Noise Operation: Engineered to minimize noise during operation, our nylon timing pulleys contribute to a quieter working environment.

5. Reduced Maintenance Needs: With robust construction and minimal wear, our pulleys require less frequent maintenance, leading to lower operational costs.

Features

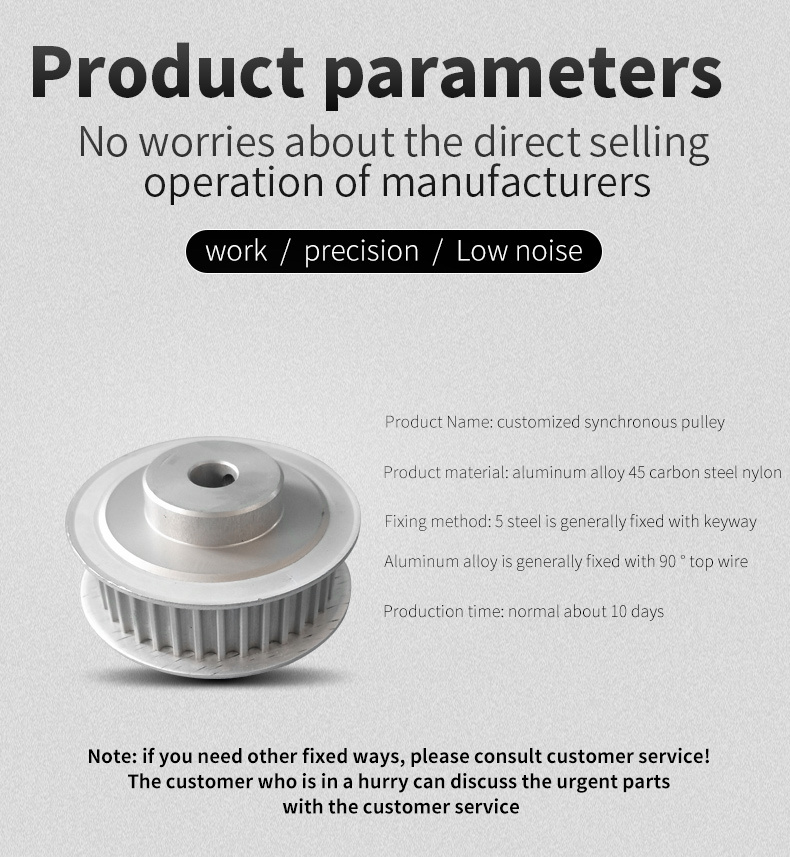

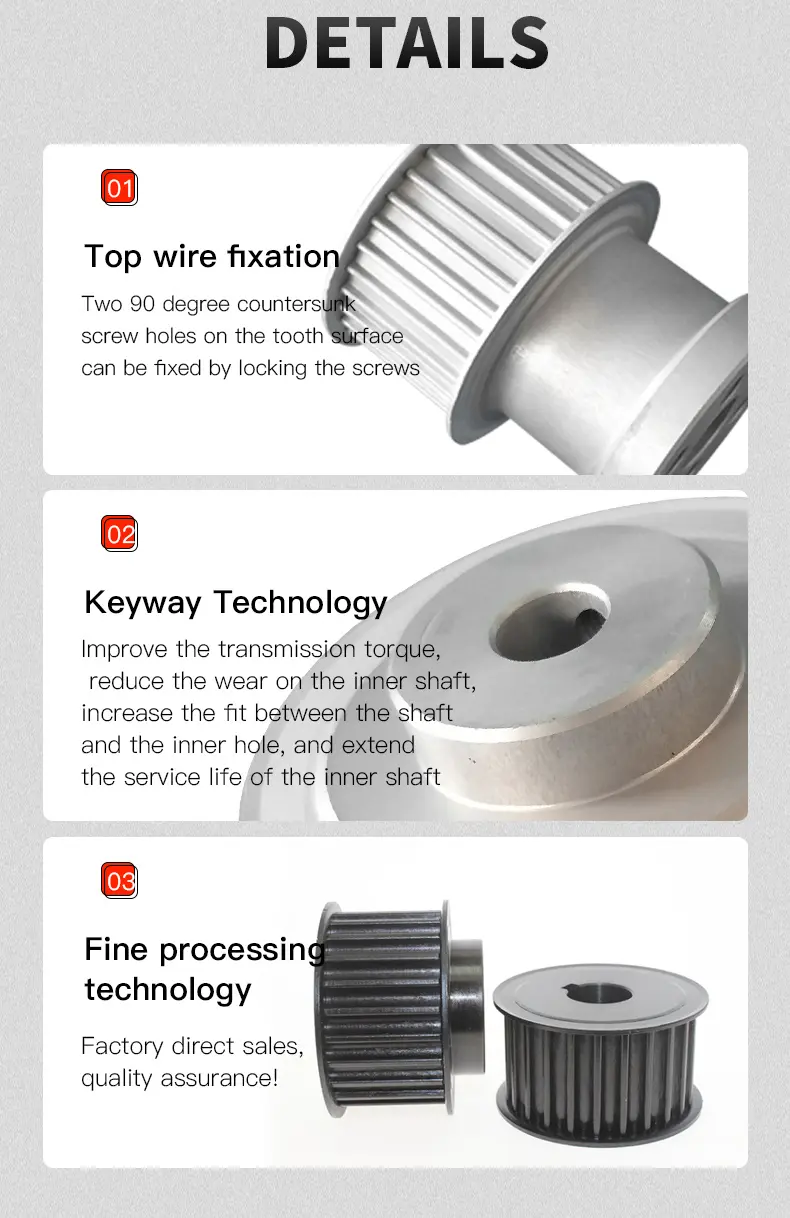

- High-Quality Material Composition: Our nylon timing pulleys are crafted from premium-grade nylon, ensuring a perfect balance of strength, flexibility, and durability.

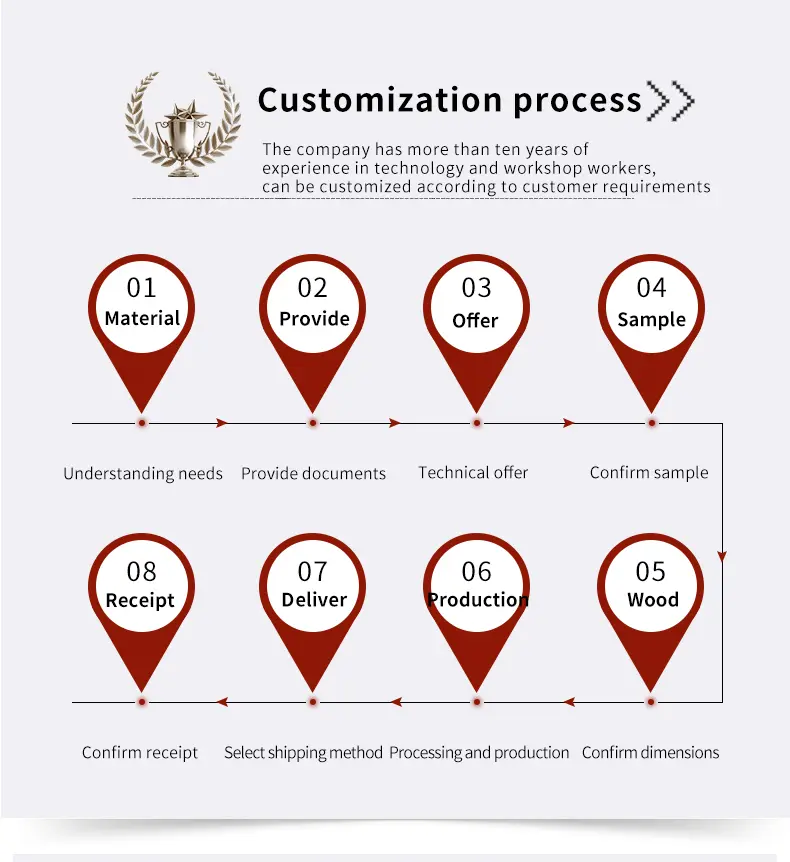

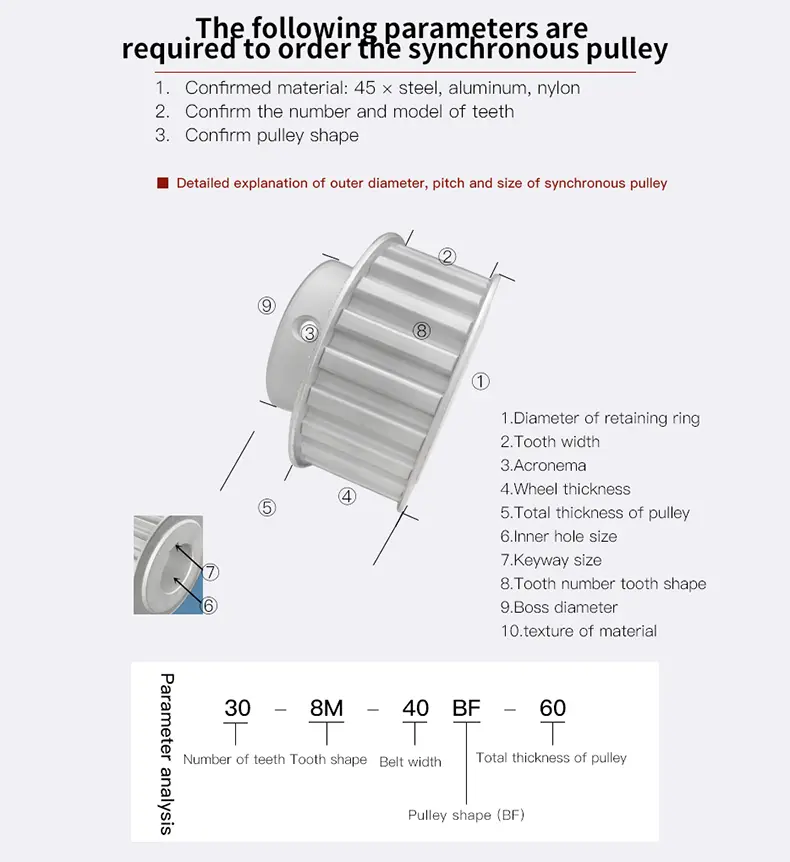

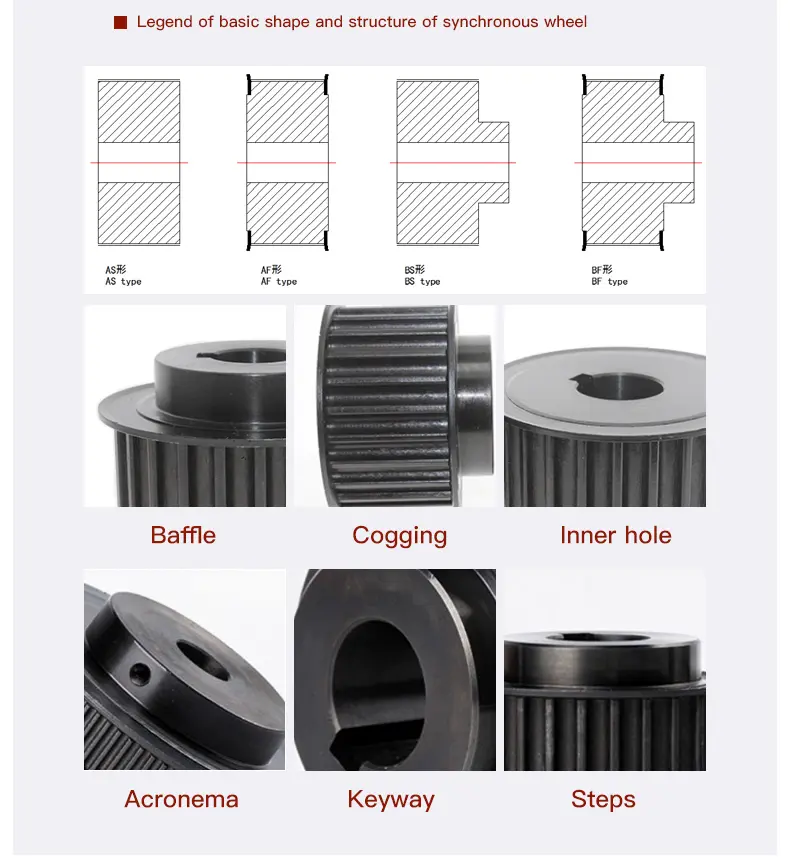

- Customizable Solutions: We offer a wide range of pulley types, including various sizes and tooth counts, tailored to meet the unique needs of your application.

- Easy Installation: Designed for straightforward installation, our pulleys can be easily integrated into existing systems, reducing downtime during maintenance.

- Eco-Friendly Manufacturing: Our nylon timing pulleys are produced using environmentally responsible processes, making them a sustainable choice for your business.

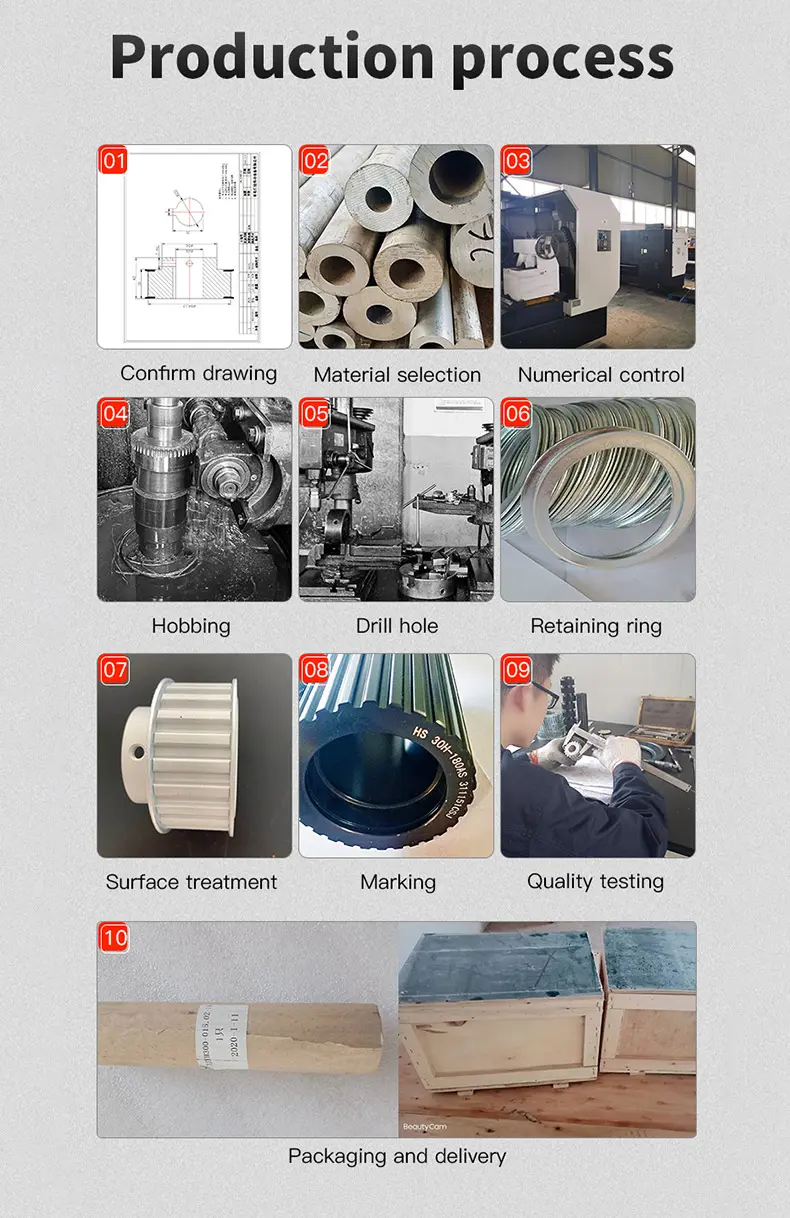

- Comprehensive Testing: Each pulley undergoes rigorous testing to ensure it meets industry standards for quality and performance, providing peace of mind for our customers.

conclusion

Investing in our high-quality nylon timing pulleys means choosing reliability, efficiency, and performance for your machinery. With their extensive applications and numerous advantages, these pulleys are the perfect solution for industries that require precision and durability. Whether you operate in manufacturing, automotive, textiles, or any other sector, our nylon timing pulleys will enhance your operational efficiency and minimize maintenance costs.

For more information or to place an order, please contact us today. Experience the benefits of high-quality nylon timing pulleys designed specifically for your machinery!