+86-19862000127

+86-19862000127

The Xl Belt Pulley plays a vital role in various mechanical applications, providing efficient power transmission in a wide array of industrial settings. According to a recent report from the Global Power Transmission Market, the demand for pulleys, including the Xl Belt Pulley, is expected to grow significantly, driven by advancements in manufacturing technologies and the increasing need for automation in industries. In fact, the power transmission market is projected to reach a value of over $25 billion by 2025, highlighting the critical importance of components like the Xl Belt Pulley in ensuring the seamless operation of machinery.

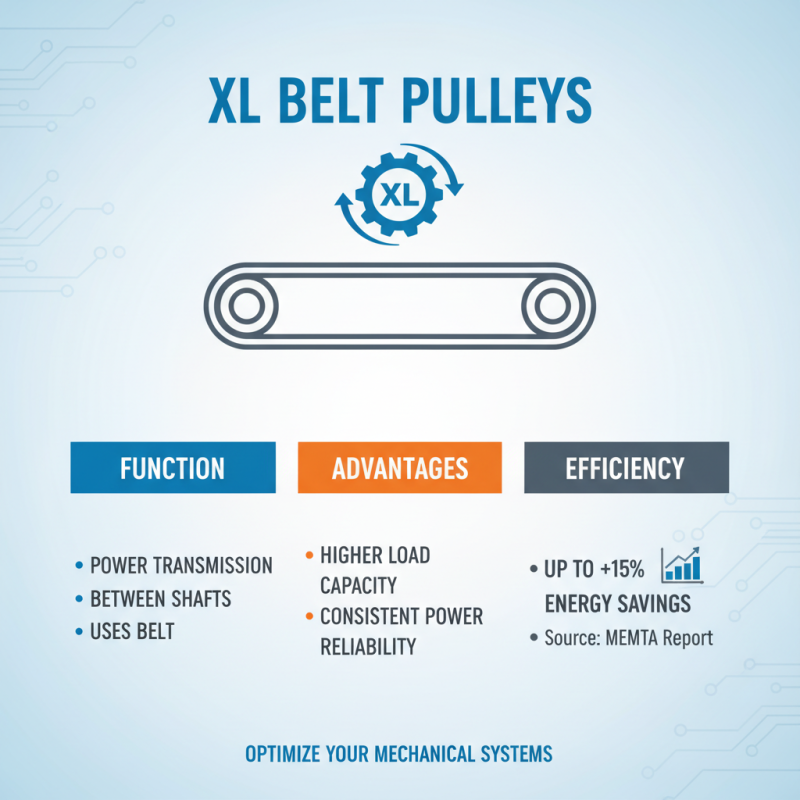

The functionality of the Xl Belt Pulley lies in its ability to transfer rotational motion and torque between shafts, allowing for optimal performance in belt-driven systems. As noted in engineering studies, the precise design of the Xl Belt Pulley contributes significantly to reduced energy losses and improved operational efficiency. With applications ranging from automotive engines to conveyor systems, understanding the mechanics of the Xl Belt Pulley not only informs best practices in equipment design but also enhances overall productivity in mechanical operations.

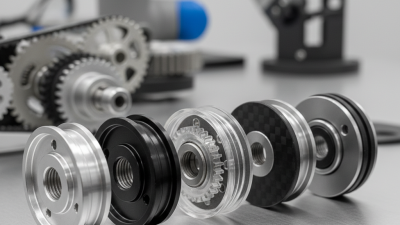

An XL belt pulley is a specific type of pulley commonly used in various mechanical applications, primarily in power transmission systems. Characterized by its wider belt grooves, the XL series is designed to accommodate XL rubber timing belts, which are known for their durability and strength. This design allows for efficient torque transfer and minimizes slippage during operation, making it ideal for applications that require precise timing, such as in conveyor systems, robotics, and various machinery.

The XL belt pulley is constructed from materials such as aluminum or steel, providing both strength and lightweight properties. Its design features a specific pitch, which ensures compatibility with corresponding belts. The pulley size can vary, allowing for flexibility in mechanical design—engineers can select pulleys of different diameters to achieve the desired speed and torque output for their systems. As a result, the XL belt pulley plays a crucial role in enhancing the efficiency and performance of a wide array of mechanical devices.

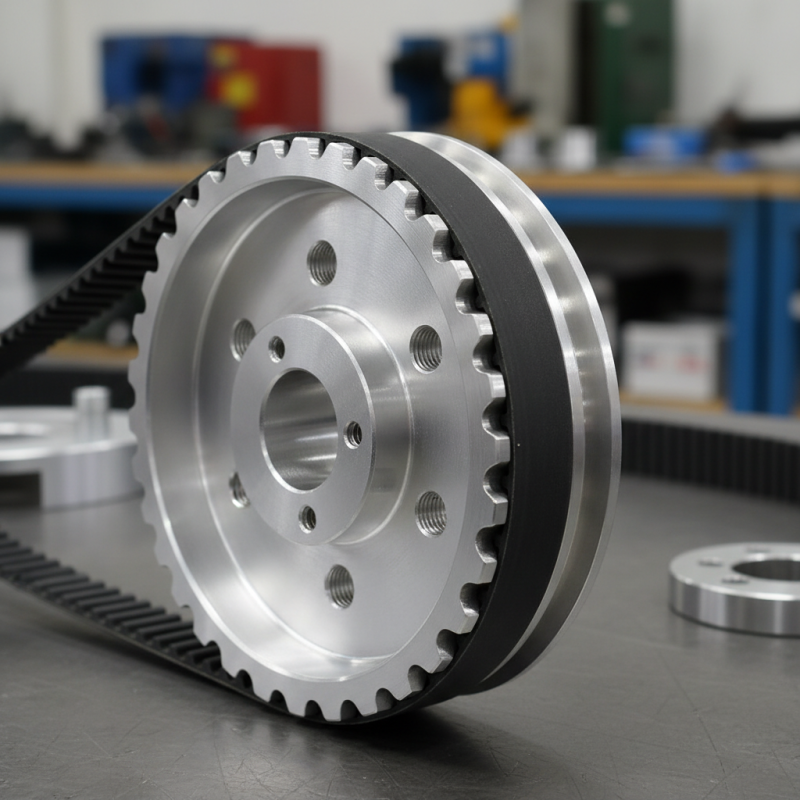

XL belt pulleys are essential components in various mechanical applications, predominantly in power transmission systems. These pulleys are designed to work with XL timing belts and are characterized by their larger diameter, which allows for effective torque transfer and speed control. A key aspect of XL belt pulleys is their construction, typically made from materials like aluminum or reinforced plastics, providing both durability and lightweight properties. According to industry reports, the demand for XL belt pulleys has been growing at a CAGR of approximately 5% in the automation sector, as companies seek efficient solutions to reduce energy consumption and improve system performance.

The primary components of XL belt pulleys include the pulley body, grooves, and mounting configurations. The pulley body is often engineered with precision to ensure minimal wear and tear, facilitating extended service life. The grooves are designed to match the XL belt's teeth, ensuring a secure fit that prevents slippage during operation. Additionally, various mounting configurations, such as set screws or keyways, enable seamless integration into existing machinery, which can be pivotal for retrofitting applications. A recent market analysis highlighted that advancements in materials and production techniques are enhancing the performance and reliability of these components, making them increasingly vital for industries such as automotive, aviation, and manufacturing.

XL belt pulleys play a crucial role in mechanical systems, particularly in power transmission applications. These pulleys feature a standardized tooth profile that enables effective engagement with XL belts, which are widely used in machinery ranging from conveyors to robotics. According to a report by the Power Transmission Distributors Association, nearly 45% of mechanical failures in industrial settings can be attributed to improper belt and pulley alignment, emphasizing the importance of correctly functioning XL belt pulleys in preventing operational disruptions.

The functionality of XL belt pulleys is primarily based on their ability to transfer rotational motion and torque. When a driving pulley rotates, it causes the XL belt to move, which then drives the corresponding driven pulley. This setup allows for the adjustment of speeds and torques throughout a mechanical system. Research from the International Journal of Mechanical Engineering shows that using an efficient pulley system can increase energy efficiency by up to 20%, making it a preferred choice in various engineering applications. Moreover, with their ability to accommodate higher loads and resist wear, XL belt pulleys are increasingly integrated into automated systems where reliability and performance are paramount.

XL belt pulleys are integral components in various mechanical applications, serving as a connection point between different parts of a system. Their primary function is to transmit power through a belt, allowing for the transfer of motion and torque in machinery. The design of XL belt pulleys accommodates a wide range of belt sizes, which makes them versatile for various uses.

One common application of XL belt pulleys is in conveyor systems, where they facilitate the movement of materials from one location to another. By connecting to electric motors or other drive sources, XL pulleys ensure efficient operation and smooth transport of goods. Additionally, they are widely used in robotics and automation, where precise motion control is crucial. The predictability and reliability of XL belt pulleys allow for seamless integration into various mechanical setups, enhancing the performance of equipment in manufacturing and assembly lines.

Another area where XL belt pulleys shine is in agricultural machinery. Equipment like tractors and harvesters often rely on these pulleys to power attachments and other essential functions. The robustness of XL belt pulleys makes them suitable for handling heavy loads and enduring harsh operating conditions, ensuring that agricultural operations run smoothly and efficiently. With their adaptability and solid performance, XL belt pulleys play a vital role in optimizing mechanical applications across numerous industries.

| Application | Description | Advantages | Typical Materials |

|---|---|---|---|

| Conveyor Systems | Used to transfer materials across different levels or distances. | Efficient movement of goods, reduced manual labor. | Aluminum, Steel, Plastic |

| Textile Machinery | Controls the speed and direction of spinning machinery. | Precise control over fabric production processes. | Steel, Cast Iron |

| Automotive Industry | Used in engines to drive ancillary components. | Increases efficiency, reduces noise. | Aluminum, Polymer |

| Agricultural Equipment | Drives equipment such as harvesters and tractors. | Enhances productivity, supports heavy loads. | Steel, Composite Materials |

| Mining Equipment | Drives crushers, conveyors, and other equipment. | Durability under harsh conditions, continuous operation. | High-Strength Steel, Rubber |

XL belt pulleys are integral components in various mechanical systems, designed to transmit power efficiently between shafts through the use of a belt. The advantages of using XL belt pulleys in engineering applications are numerous, particularly in terms of their performance and versatility. One of the primary benefits is their ability to handle higher load capacities while maintaining a consistent power transmission, which is critical in industrial settings where reliability is paramount. According to a report from the Machinery and Equipment Manufacturers Association, using XL pulleys can increase the efficiency of power transmission systems by up to 15%, significantly reducing energy costs over time.

Moreover, XL belt pulleys are designed to accommodate a range of belt sizes and types, making them highly adaptable for various mechanical configurations. Their standardized dimensions ensure compatibility with other components, simplifying the design and assembly processes. A study conducted by the American Society of Mechanical Engineers highlighted that the use of standardized pulleys decreases manufacturing time by as much as 20%, allowing engineers to optimize their workflows effectively. Additionally, the robust construction of XL pulleys contributes to lower maintenance requirements, further enhancing their attractiveness for engineering applications where uptime and operational efficiency are critical.