+86-19862000127

+86-19862000127

In the realm of precision engineering and robotics, the choice of components can significantly influence the performance and reliability of the final product. One such crucial component is the 5mm GT2 pulley, a device that facilitates efficient power transmission and precise movement in various applications. As technology advances, the demand for high-quality, reliable pulleys has never been more critical. Scott Anderson, a leading expert in mechanical engineering, emphasizes this necessity: "The precision of your machinery directly correlates with the quality of the components you choose. 5mm GT2 pulleys stand out for their ability to provide both accuracy and durability."

As we move toward 2025, choosing the right 5mm GT2 pulley can make or break a project in both industrial and robotics settings. With numerous options available, it's essential to evaluate which pulleys offer the best performance, compatibility, and longevity for specific applications. In this article, we will explore the top five 5mm GT2 pulley options on the market, focusing on their unique features and advantages. By understanding the strengths and limitations of each option, engineers and hobbyists alike can make informed decisions that will enhance their projects' overall effectiveness and efficiency.

When it comes to precision engineering and robotics, the choice of pulleys plays a critical role in the overall performance of mechanical systems. The GT2 5mm pulleys are particularly popular due to their design, which minimizes backlash and increases efficiency in power transmission. This overview explores five exceptional options, each catering to the specific needs of precision applications.

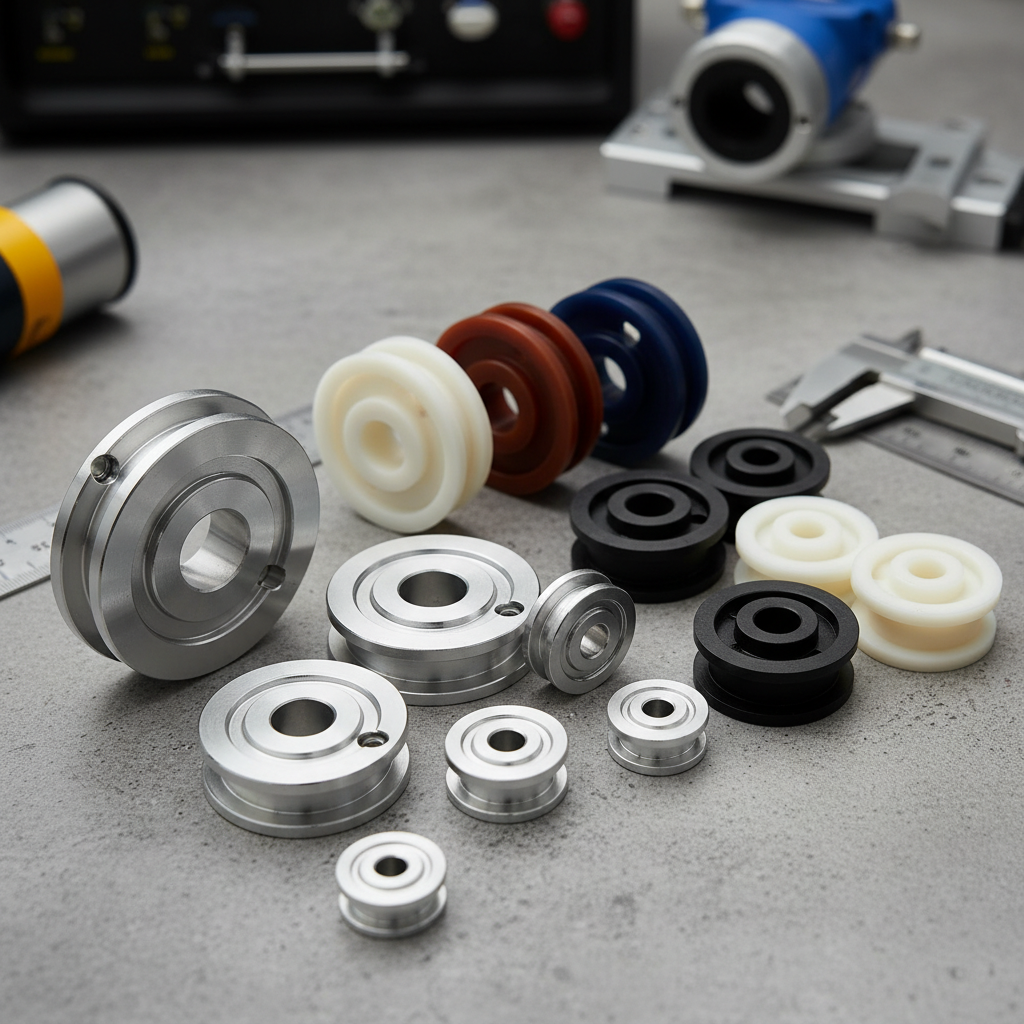

One standout option is the aluminum GT2 pulley, known for its robust build and lightweight characteristics. This makes it ideal for high-speed applications where durability is essential. Additionally, a selection of plastic GT2 pulleys offers a cost-effective solution without sacrificing precision. These are perfect for low-load environments, where weight saving is essential. For even finer control, timing belts and pulleys with wider teeth ensure smoother operation and reduced wear, making them suitable for advanced robotics applications that require high accuracy and repeatability.

When selecting high-performance GT2 pulleys for precision engineering and robotics applications, several key features must be prioritized to ensure optimal performance. First and foremost, the material composition of the pulleys plays a critical role in their durability and efficiency. Aluminum and reinforced plastic are popular choices; aluminum offers superior strength and heat resistance, while plastic can provide a lightweight option with good wear characteristics, facilitating smoother operations in high-speed environments.

Another essential feature to consider is the pulley’s tooth profile and pitch accuracy. High-precision pulleys with well-defined tooth profiles ensure minimal backlash and improved synchronization, which is crucial for applications that demand exact positioning, such as robotics. The manufacturing process, including CNC machining or injection molding, can significantly affect the precision and consistency of the pulley dimensions. Additionally, features like surface finish and lubrication options contribute to reducing friction and wear, ultimately enhancing the lifespan and performance of the drive system in demanding applications.

When selecting GT2 pulleys for precision engineering and robotics applications, the choice of material plays a crucial role in performance, durability, and overall system efficiency. The most common materials used for GT2 pulleys include aluminum, plastic composites, and engineered resins. Aluminum pulleys, renowned for their strength and rigidity, are ideal for high-load applications. They offer excellent wear resistance, making them suitable for environments where longevity and precision are critical. However, their weight and cost may be a consideration for some applications.

On the other hand, plastic composites and engineered resins present a viable alternative, particularly in lightweight and cost-sensitive projects. These materials can provide adequate strength and excellent resistance to corrosion and abrasion. For instance, Nylon GT2 pulleys are widely known for their low friction properties, which can enhance the efficiency of motion systems. Additionally, they can dampen vibrations, making them beneficial in robotics applications where precision is paramount. Ultimately, the choice between these materials will depend on the specific requirements of the project, including load capacity, operating environment, and budget constraints.

GT2 pulleys have become essential components in robotics and precision engineering projects due to their ability to deliver high accuracy and reliability in motion control. These pulleys are specifically designed for use with GT2 timing belts, which provide minimal backlash and enhanced power transmission. Recent industry reports indicate that the adoption of GT2 pulleys has surged, particularly in applications such as 3D printers and CNC machines, where precision is paramount. For instance, market studies project a CAGR of 7.5% in the robotics sector, highlighting the increased reliance on precision components like GT2 pulleys in the development of advanced robotic systems.

The versatility of GT2 pulleys makes them ideal for projects like the Arduino-controlled plotter, Cartesio. By integrating these pulleys into its design, Cartesio can achieve smooth and precise movements, essential for creating intricate artwork. The use of high-quality GT2 pulleys not only enhances performance but also extends the lifespan of the robotic system by reducing wear and tear. Furthermore, as the demand for custom robotic systems grows, engineers are increasingly turning to GT2 pulleys for their ability to support a wide range of applications, from industrial automation to educational robotics.

The future of GT2 pulley technology is being shaped by innovative designs that prioritize efficiency and precision in engineering and robotics. Advanced materials and manufacturing techniques are driving the development of pulleys that not only lower friction but also enhance durability. The incorporation of 3D printing technology allows for intricate designs that can be tailored to specific applications, resulting in lightweight yet robust components that meet the stringent demands of modern machinery.

Moreover, the integration of smart technology into pulley systems is an emerging trend. Sensors that provide real-time feedback on performance metrics such as tension and wear are becoming a staple in high-performance setups, allowing for predictive maintenance and minimizing downtime. As the industry moves toward automation and intelligent systems, these innovations in GT2 pulley design will play a critical role in optimizing performance, making them indispensable in the realms of precision engineering and robotics.