+86-19862000127

+86-19862000127

In the world of material handling, the Mounted Pulley is a key component in optimizing efficiency. According to industry data from the Material Handling Industry of America, nearly 60% of warehouse operations utilize pulley systems to improve lifting performance. These systems play a pivotal role in reducing physical strain and enhancing productivity.

However, proper implementation and understanding of the Mounted Pulley are often overlooked. Many users believe that merely installing a pulley will yield significant benefits. Yet, without knowledge of best practices, misuse can lead to injury or equipment malfunction. The lack of training can be costly—companies lose about $85 billion annually due to workplace injuries caused by improper equipment use.

A Mounted Pulley can be a game-changer if used effectively. Familiarity with load limits, angles, and mounting techniques can enhance safety and performance. The right setup can minimize wear and tear, but a lackadaisical approach may result in frequent replacements or even accidents. Understanding these factors is crucial for optimizing the benefit of Mounted Pulleys in any operation.

Mounted pulleys are simple but powerful tools that enhance efficiency in various tasks. Understanding the basics is crucial for effective use. A mounted pulley consists of a wheel and a fixed axle. It redirects force in a desired direction, allowing heavy loads to be moved with less effort. According to industry reports, using mounted pulleys can reduce the required force by up to 50%. This makes them valuable in both industrial and home applications.

When employing mounted pulleys, proper installation is key. The pulley must be securely fixed to prevent movement during use. Additionally, the rope or cable should fit snugly in the groove. Industry data suggests that improper installation can lead to accidents, causing injuries or equipment failure. It's essential to regularly inspect and maintain your pulley system. Check for wear and replace components as needed.

Efficiency often comes with challenges. Overloading a pulley can lead to dangerous situations. The American National Standards Institute recommends checking the weight limit of your system. Many users overlook this, leading to frustrations and potential hazards. Using mounted pulleys requires careful planning and attention to detail. Emphasizing safety and proper usage practices can enhance their effectiveness in everyday tasks.

When selecting the right mounted pulley, consider your specific needs. The weight capacity is crucial. Different projects require various strengths. A pulley designed for heavy loads will not suit lighter tasks. Assess the weight you plan to lift. Do not underestimate this aspect.

Material is another important factor. Pulley materials can range from metal to durable plastics. Metal pulleys offer longevity but may add more weight. Plastic options are lighter but could wear over time. Think about how often you’ll use the pulley. Frequent usage demands a sturdier choice.

Installation is often overlooked. Make sure you know how to set it up properly. A poorly installed pulley can lead to accidents or failure. It’s wise to practice before your main project. Take your time and learn from any mistakes. Ultimately, the right pulley enhances your efficiency and safety in any task.

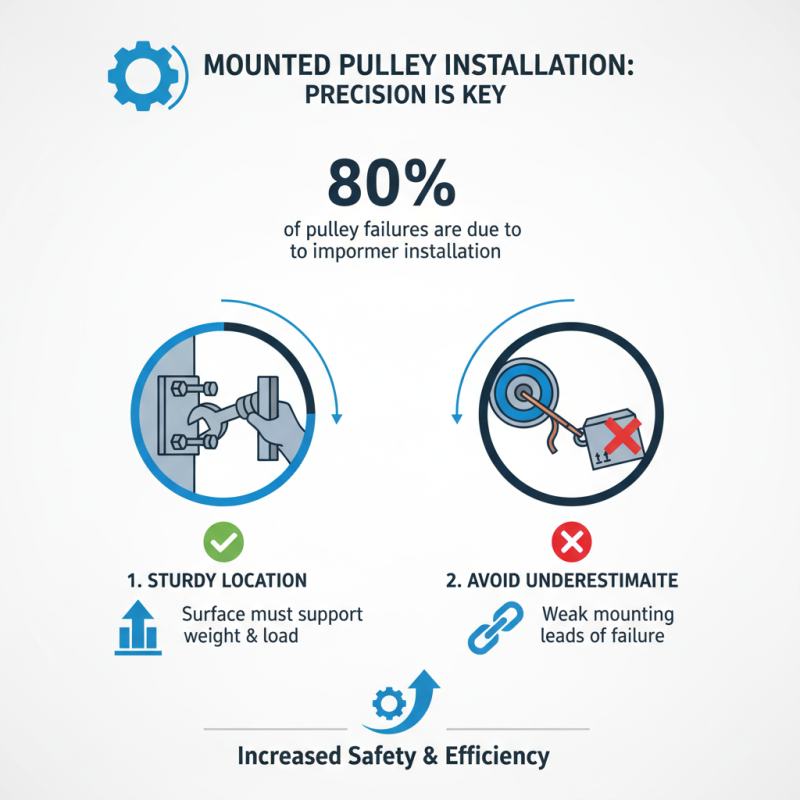

When installing a mounted pulley, precision is key. Start by selecting a sturdy location. The surface must support the pulley’s weight and the load it will bear. Studies suggest that at least 80% of pulley failures occur due to improper installation. Users often underestimate this aspect.

Next, ensure accurate alignment with the intended load path. Misalignment can lead to friction and wear, drastically reducing efficiency. According to the American Society of Mechanical Engineers, misalignment can decrease pulley life by an alarming 30%. Use a level to maintain a straight line.

Finally, secure the pulley with appropriate fasteners. Avoid using cheap materials that may buckle under pressure. Inspect all components for damage. Even a small crack can cause significant safety issues. Regular maintenance checks can help identify problems early. Proper installation and continuous monitoring lead to effective use of mounted pulleys.

Mounted pulleys are versatile tools. When using them, proper techniques can greatly enhance your efficiency. One common mistake is poor positioning. The pulley should be positioned at an optimal height. This can minimize strain and maximize your leverage. Pay attention to the angle of the rope as well. An incorrect angle can lead to unnecessary friction and wear.

Another technique involves knowing your limits. Don't attempt to lift loads that exceed your strength. It's important to assess the weight carefully. Using the pulley should simplify your task, not complicate it. Regularly inspecting the pulley system is crucial. This can help identify wear and tear before it becomes an issue.

Finally, practice makes perfect. Missteps might happen initially. You might struggle with fluidity and coordination. Reflecting on these experiences can provide valuable insights. Keeping a notebook of your attempts could aid in improving your technique. Consistency is key in mastering mounted pulley use.

When using mounted pulleys, safety is paramount.

Always wear proper personal protective equipment. Hard hats and gloves can greatly reduce the risk of injury. Inspect the pulley system before each use. Look for signs of wear or damage. A worn pulley can fail unexpectedly.

Be aware of your surroundings. Keep the area clear of unnecessary personnel. Ensure that everyone knows the plan. Clear communication can prevent accidents. It's vital to understand how much weight your pulley can safely handle.

Overloading can cause equipment failure.

Regular training is crucial. Even experienced operators can overlook safety protocols. Frequent revisions on safety practices help maintain a safe working environment. Always maintain a safety-first mindset, even on routine tasks. Remember, safety isn’t just a checklist; it requires constant vigilance and reflection.