+86-19862000127

+86-19862000127

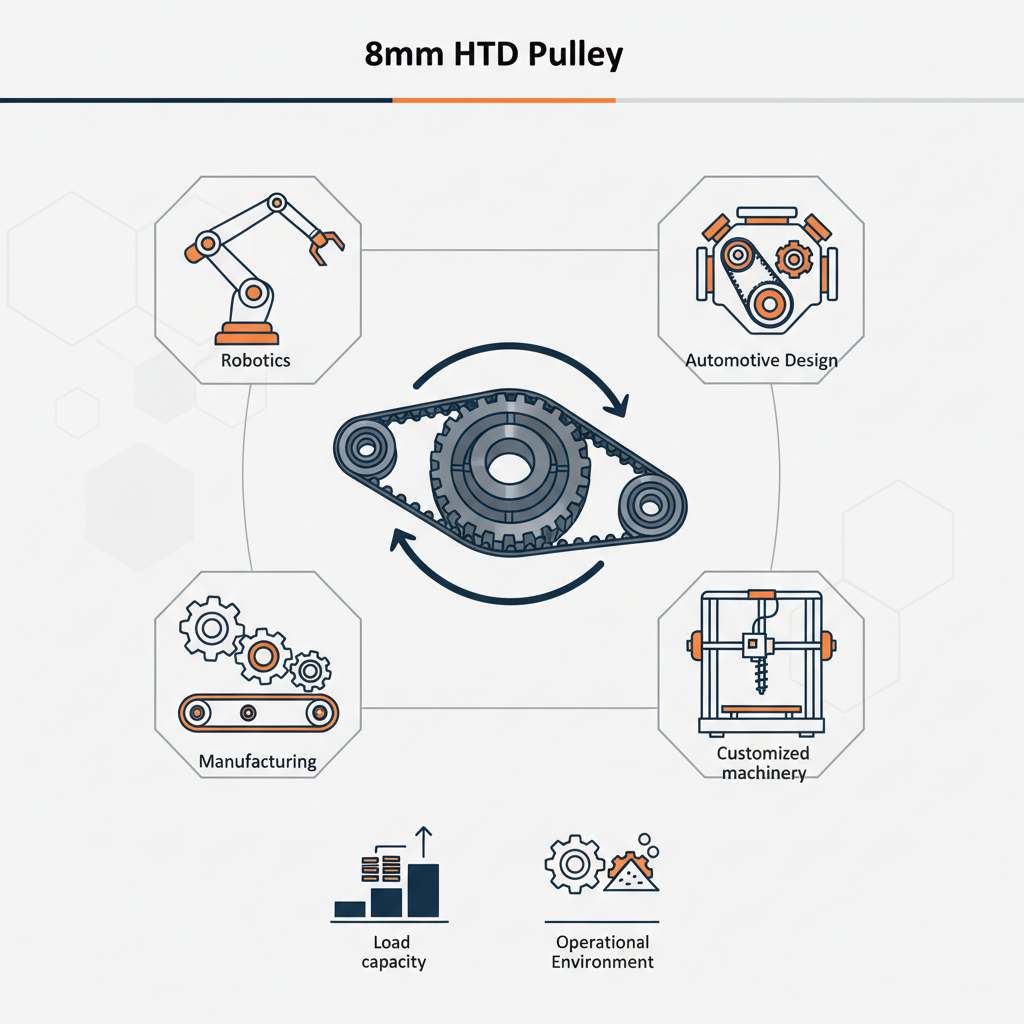

The 8mm Htd Pulley plays a pivotal role in various mechanical and engineering applications, especially in the fields of robotics, automotive design, and manufacturing. According to a recent industry report by the Global Pulley Market Association, the demand for high-precision pulleys like the 8mm Htd variant is projected to grow by 15% annually, driven by advancements in automation and the increase in customized machinery. As manufacturers strive for improved efficiency and reliability, selecting the right pulley becomes crucial.

Industry expert Dr. Emily Carter, a noted authority on mechanical components, emphasizes, "An accurately chosen 8mm Htd Pulley not only enhances system performance but also significantly extends operational lifespan." Her insights highlight the importance of understanding specific requirements, such as load capacity and the operational environment, when making the selection. With the increasing prevalence of such components in both industrial and hobbyist settings, comprehending the technical specifications and compatibility of 8mm Htd Pulleys becomes essential for optimizing performance and ensuring durability.

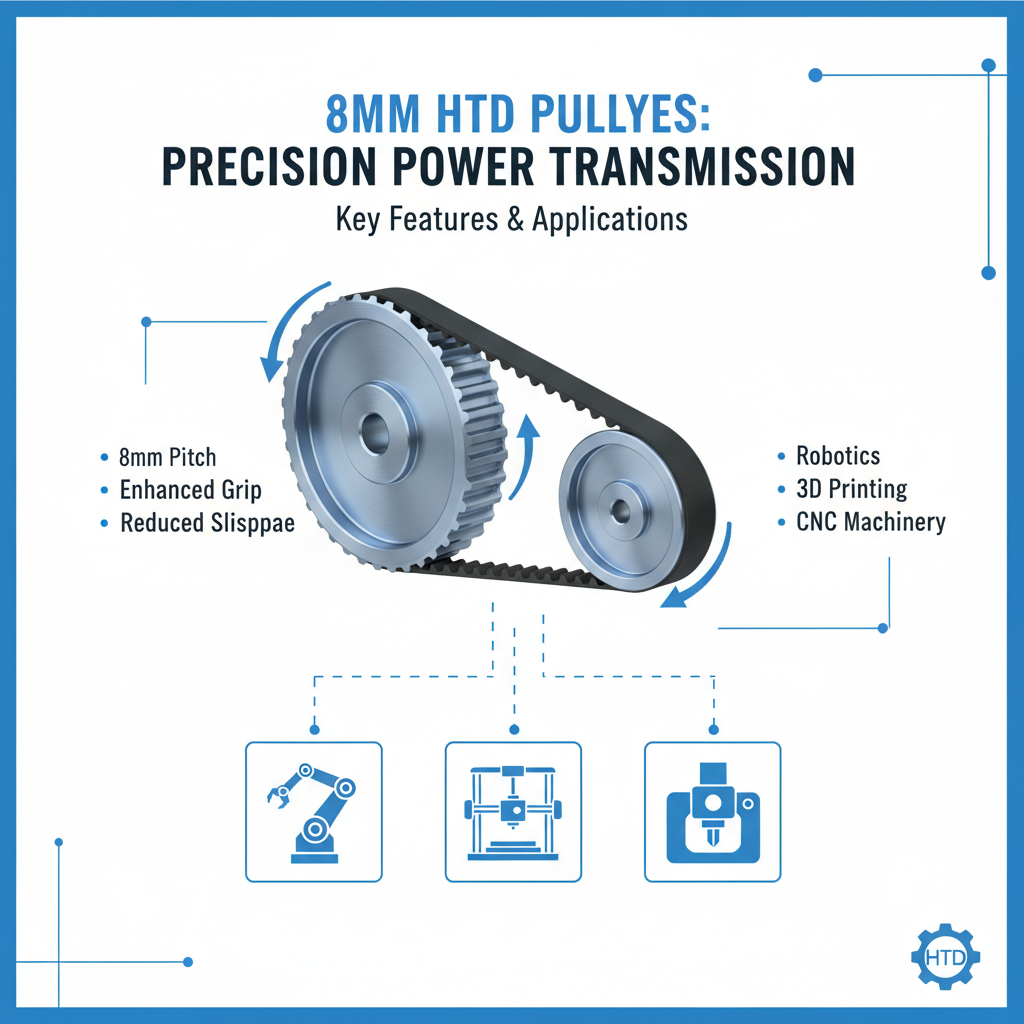

8mm HTD (High Torque Drive) pulleys are commonly used in various mechanical systems to transmit power efficiently. Characterized by their 8mm pitch, these pulleys are designed for compatibility with HTD belts, which feature a tooth profile that enhances grip and minimizes slippage. This design is critical in applications where reliability and precision are paramount, making 8mm HTD pulleys a favored choice in robotics, 3D printing, and CNC machinery.

When selecting the right 8mm HTD pulley, several factors must be considered. The material of the pulley can significantly affect its durability and performance; for instance, aluminum offers lightweight properties, while steel provides increased strength. Additionally, one should assess the number of teeth on the pulley, as this will influence the speed and torque characteristics of the system. It is also essential to ensure that the pulley’s bore size matches the shaft on which it will be mounted, facilitating a secure fit and optimal function. Understanding these basics is crucial for making an informed decision in the selection of the appropriate 8mm HTD pulley for your specific application.

When considering an 8mm HTD pulley, it's essential to focus on its key features and specifications to ensure it meets your specific application needs. HTD (High Torque Drive) pulleys are designed to provide efficient power transmission while minimizing slippage. The 8mm pitch design is particularly beneficial for applications that require high precision and torque. Key specifications to consider include the number of teeth, material composition, and the groove profile, which together influence the pulley’s performance and compatibility with various belts.

Another important aspect is the pulley’s load capacity and operating environment. Depending on whether the application is light-duty or heavy-duty, you might require pulleys made from different materials such as aluminum for lightweight projects or steel for high-strength needs. Furthermore, selecting the right pulley often involves assessing the installation space and the type of motor used, ensuring that the pulley aligns perfectly with the drive system for optimal efficiency. Understanding these features will aid in making an informed choice, thus enhancing the overall performance of your mechanical system.

When choosing an

8mm HTD pulley, there are several factors to consider to ensure optimal performance.

First, assess the type of material used in the pulley construction. Common materials include

aluminum,

plastic, and

steel, each offering different levels of strength, durability, and weight.

Aluminum pulleys tend to be lightweight and corrosion-resistant, making them a popular choice for various applications, while

plastic options might be suitable for lighter loads.

Another important factor is the number of teeth on the pulley. The number of teeth will affect the gear ratio and the overall speed and torque of your application.

A pulley with fewer teeth may provide higher speeds, but it can also lead to increased wear on the belt over time. Therefore, consider the specific needs of your project

and balance speed with durability.

Tips:

8mm HTD pulleys are widely utilized across various industries due to their efficiency in power transmission and ability to maintain precise timing. In the automotive sector, these pulleys play a crucial role in belt drives, facilitating the smooth operation of engine components such as camshafts and crankshafts. Their design allows for high torque capability, making them ideal for performance vehicles that require reliable power transfer without slippage.

In addition to automotive applications, 8mm HTD pulleys find significant use in robotics and automation. They are essential in driving systems where consistent movement and accuracy are paramount. For instance, they can be found in 3D printers, CNC machines, and conveyor systems, where they ensure that components move in sync without delays or interruptions. This versatility makes them invaluable for improving productivity and efficiency in production lines and manufacturing processes.

| Application Area | Common Uses | Choosing Factors | Recommended Material |

|---|---|---|---|

| Automotive | Timing belts and drive systems | Torque requirements, load conditions | Aluminum alloy |

| Industrial Machinery | Conveyor systems, robotic arms | Speed ratios, operational efficiency | Steel or anodized aluminum |

| Home Appliances | Washing machines, food processors | Space constraints, weight | Plastic or composite materials |

| Bicycle Components | Gear systems, e-bikes | Weight, durability | Aluminum or carbon fiber |

| 3D Printers | Drive mechanisms, belt systems | Precision, noise levels | Plastic, metal for improved rigidity |

When installing an 8mm HTD pulley, precision is key to ensure optimal performance. Begin by selecting the correct mounting position, ensuring that the pulley aligns perfectly with the driven component. Misalignment can lead to increased wear and inefficiency. Additionally, make sure that the mounting surface is clean and free from debris to achieve a good fit. It's advisable to use appropriate tools for tightening the pulley's fasteners, maintaining uniform pressure without over-tightening, which could damage the pulley and bearings.

Maintenance of your 8mm HTD pulleys is equally important to extend their lifespan. Regularly check for signs of wear, including cracks or surface degradation, which can compromise their effectiveness. Lubrication might be necessary depending on your specific application, so refer to the manufacturer's guidelines for the correct type of lubricant. Furthermore, inspecting the tension of the connected belt is crucial; it should be neither too tight nor too loose to prevent slippage and ensure efficient power transmission. Implementing a routine maintenance schedule will help catch potential issues early and maintain peak performance in your system.